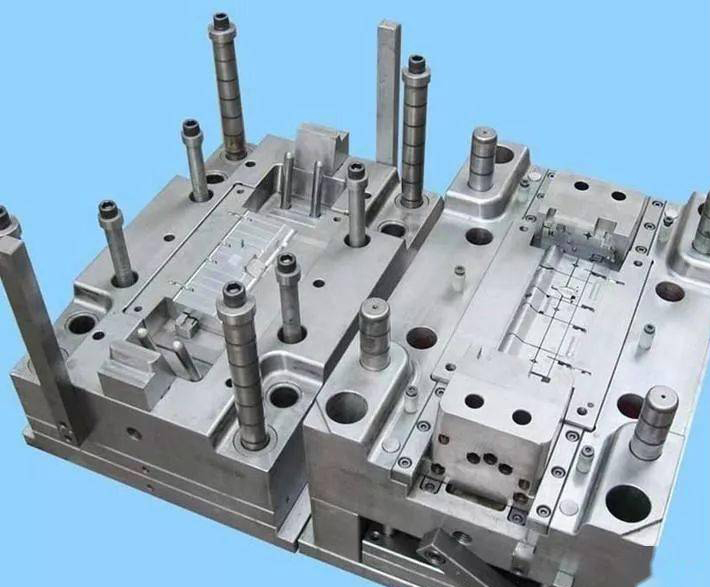

Among the related factors that affect precision injection molding, molds are the key to obtaining precision plastic products that meet quality requirements.

The mold design and whether the mold design is reasonable will directly affect the quality of plastic products. Since the mold cavity size is derived from the required size of the plastic product plus the shrinkage rate of the material used, the shrinkage rate is often a value within a range recommended by the plastic manufacturer or engineering plastics manual. It is not only related to the gate form, gate location and distribution of the mold, but also related to the crystal orientation (anisotropy) of engineering plastics, the shape and size of the plastic product and the distance and location of the gate.

The main factors affecting plastic shrinkage include thermal shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage and elastic recovery.

These influencing factors are related to the molding conditions or operating conditions of precision injection molded products. Therefore, mold designers must have rich design and injection molding experience, and must consider the relationship between these influencing factors and injection conditions and their apparent factors, such as injection pressure and cavity pressure and filling speed, injection melt temperature and mold temperature , mold structure and gate form and distribution, and the influence of factors such as gate cross-sectional area, product wall thickness, reinforcing filler content in plastic materials, crystallinity and orientation of plastic materials

The influence of the above factors is also different due to different plastic materials, or other molding conditions such as temperature, humidity, continued crystallization, and changes in the injection molding machine after molding.

Because the injection molding process is a process of transforming plastics from solid (powder or pellets) to liquid (melt) to solid (product). From the pellets to the melt, and then from the melt to the product, the temperature field, flow field and density field must be affected in the molding process..

Under the combined action of these fields, different plastics (thermosetting or thermoplastic, crystalline or non-crystalline, reinforced or non-reinforced, etc.) have different polymer structural morphologies and rheological properties. Anything that affects the above factors will definitely affect the physical and mechanical properties, size, shape, precision and appearance quality of plastic products.