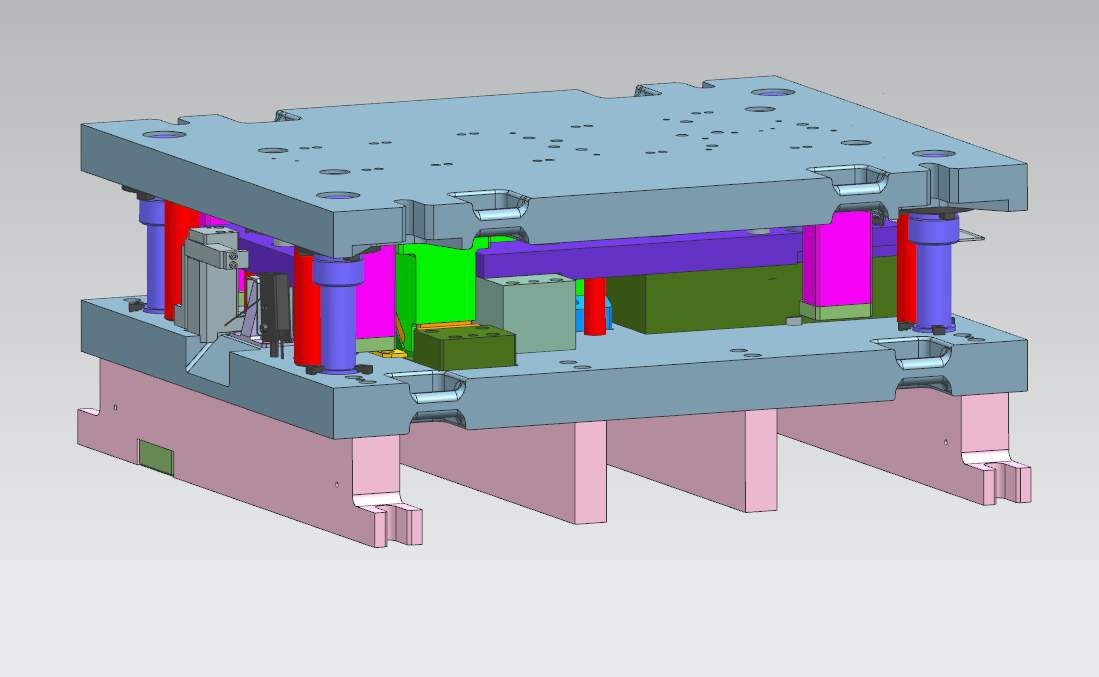

Notes for a new set of models , what processes are needed, and what are the technical requirements, maybe each designer and company have their own styles and methods. However, if the experience is not rich, there will always be various problems in designing and debugging.

The editor believes that a relatively complete design and mold trial process should be carried out according to the following key points. And it is suitable for all stages and different types of mold design, as follows:

Don't rush to start painting when you get the product. You should understand the product structure, the product's dimensional accuracy requirements, product material types, and whether there is a clear stamping direction, and the number of products.

When preparing a process, it is best to use simulation analysis software such as AF or DF for analysis, so as to obtain specific parameters to facilitate communication with customers, and also to understand the rationality of the product process before mold opening, reducing the trial period . (Note: If the customer has opened a similar mold before, it is best to have drawings for reference)

In the design of automobile molds, the design essentials of continuous molds give priority to floating material structure and must ensure smoothness. Because automobile parts are generally larger and thicker, the material belt will be heavier. If the final material belt cannot float due to improper considerations, it will be a fatal problem.

When the size of the product has special requirements or the tolerance level is high, the mold structure that completes this process should be made as movable and adjustable as possible to facilitate the subsequent shifting of the mold.

In order to ensure uniform force and elastic force, the elastic elements in automobile molds generally use nitrogen gas springs. However, the number of springs needs to be discharged according to the CAE analysis of the pressing force value.

If the springs in the mold are arranged too densely, the product is easy to be cracked, and the tonnage of the press needs to be increased accordingly. If the spring is too small, the product will tend to wrinkle.